Features

|

Benefits

|

Applications

|

Specifications |

Electrical

Ratings Compliance

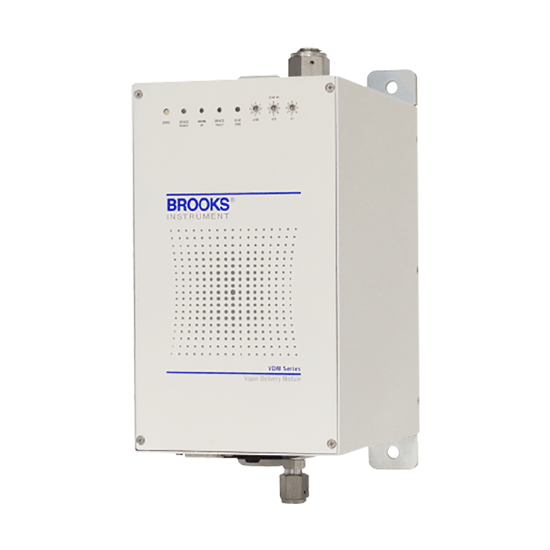

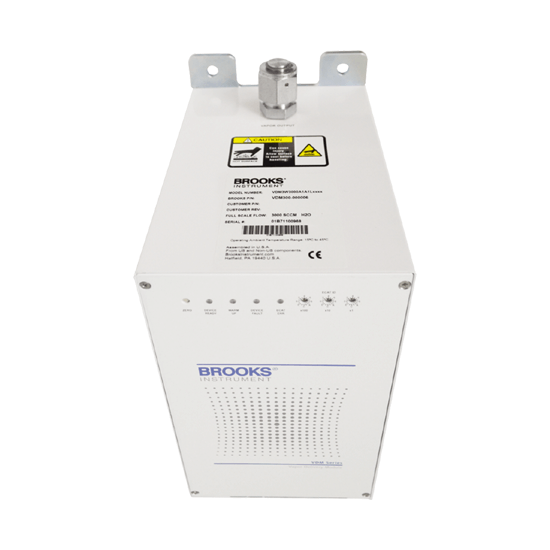

| Product Type | DI Water Vapor Delivery Module |

| Differentiator | Ultra High Purity DIW Vapor Highest Flow Accuracy Compact Design EtherCAT interface |

| Vaporization Method | Vapor Draw |

| Fluid Type | UHP DI Water |

| Flow Range (Full Scale Capacity) | 3000 sccm |

| Turndown Ratio | 20:1 |

| Response Time | <2 sec |

| Accuracy | ±1% SP @ >10% FS ±0.2% FS @ 5 – 10% FS |

| Linearity | ±0.5% of FS |

| Repeatability | <±0.2% FS |

| Flow Temperature Coefficient | 0.05% per °C zero and span |

| Valve Shut Down | Normally Closed Valve: <0.5% FS |

| Analog Communication | 0 to 5-24 Vdc |

| Digital Communication | EtherCAT via dual RJ-45 jacks Diagnostic (RS485) via microUSB |

| Electrical Connection | 208-230 Vac, 50/60 Hz, 290 Watts Nominal (tank heater) ± 15 Vdc, ± 5% @ 1.2 amp (MFC heater and PCBA) |

| Status Lights | Zero Device Ready Warm Up Device Fault ECAT Error EtherCAT Run EtherCAT Link Active |

| Diagnostic / Service Port | RS-485 via microUSB |

| Fittings | Outlet Vapor: 1/2″ Female VCR Inlet DI Water: 1/4″ Male VCR or Tube Compression DI Water Drain: 1/8″ Instant Tube Fitting |

| Mounting Orientation | Vertical with DIW inlet fittings down |

| Max Pressure | Vapor Outlet: 200 torr |

| Supply Pressure | DI Water: 10 – 40 psig N2 Purge: 10 – 40 psig |

| Ambient Temperature Range | 15 – 45°C |

| Internal Volume | 0 to 95% RH, non-condensing |

| EMC | Electromagnetic Compatibility (EMC): Fully Compliant to Directive 2004/108/EC (EN: 61326-1:2013) Low Voltage Directive (LVD): Fully Compliant to Directive 2006/95/EC (EN: 61010-1:2010) |

| Environmental Compliance | RoHS Directive (2011/65/EU) REACH Directive EC 1907/2006 SEMI E54.20-1108: Standard for Sensor/Actuator Network Communication for EtherCAT® |