Features

|

Benefits

|

Applications

|

Specifications |

Performance Ratings Electrical

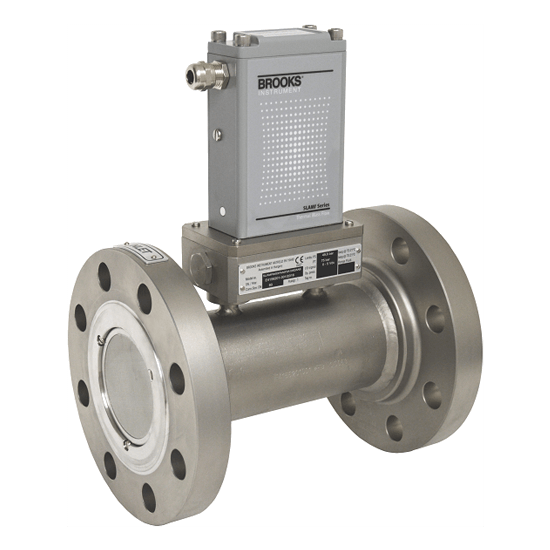

| Product Type | |

| Differentiator | NEMA 4X/IP66 Approved Enclosure Perfect for Hose Down/Wash Down Applications Hazardous Area Approvals |

| Flow Range (Full Scale Capacity) | .003 – 2500 slpm |

| Accuracy | Up to 100 lpm: 0.90% of SP (20-100% FS) 0.18% of FS (2-20% FS, 1-20% FS from 1 – 50 lpm) 100 – 2500 lpm: 0.90% of SP (20-100% FS) 100 – 1100 lpm: 0.18% of FS (2-20% FS) 1100 – 2500 lpm: 1.0% of FS |

| Repeatability | 0.20% SP |

| Linearity | Included in Accuracy |

| Response Time | <1 second up to 100 lpm <3 seconds up to 2500 lpm |

| Multi-Gas & Range Configurability | Standard |

| Max Pressure | Up to 100 lpm: 1500 psi/100 bar Up to 50 lpm: 4500psi/310 bar (optional) 100-2500 lpm: 1000 psi/70 bar |

| Control Range | 1-50 slpm: 100:1 Turndown for F.S. 50-2500 lpm: 50:1 Turndown for F.S. |

| Zero Stability | < 0.2% F.S. per year |

| Flow Temperature Coefficient | Zero: <0.05% of F.S. per °C Span: < 0.1% of S.P. per °C |

| Pressure Coefficient | ±0.03% per psi (0-200 psi N2) |

| Attitude Sensitivity | <0.2% F.S. maximum deviation from specified accuracy after re-zeroing |

| Max Temperature | 65oC |

| Differential Pressure Range | Controllers Up to 50 lpm: 5 psi/0.35 bar min – 1500 psi/103.4 bar max 50-100 lpm: 10 psi/0.69 bar min – 50 psi/3.45 bar max 500 lpm: 7.5 psi/0.52 bar min – 300 psi/20.0 bar max 1000 lpm: 14.5 psi/1.00 bar min – 300 psi/20.0 bar max 2500 lpm: 35.0 psi/2.41 bar min – 300 psi/20.0 bar max |

| Leak Integrity | 1×10-9 atm cc/sec He |

| Mechanical | |

| Seal Material | Elastomer Seal |

| Wetted Materials | 316L Stainless Steel High Alloy Stainless Steel Viton® Fluoroelastomers Buna-N Kalrez® Teflon®/Kalrez® EPDM |

| Valve Options | Normally Closed Normally Open Meter (no valve) |

| Diagnostics | |

| Diagnostic Capability | Available |

| Status Lights | MFC Health, Network Status |

| Alarms | Sensor Output Control Valve Output Over Temperature Power Surge/Sag Network Interruption |

| Diagnostic / Service Port | RS485 via 2.5mm jack |

| Analog Communication | 0-5 V, 1-5 V, 0-10 V, 0-20 mA, 4-20 mA |

| Digital Communication | DeviceNet™ FOUNDATIONTM Fieldbus Profibus® RS485 |

| Electrical Connection | DeviceNet™: 1 x M12 with threaded coupling nut (B) Profibus®: 1 x 15-pin Male Sub-D 1 x 9-pin female Sub-D RS485: 1 x 15-pin Male Sub-D, (A) |

| Power Supply / Consumption | Analog / Profibus® / RS-485 Valve Orifice > 0.032″: 8 Watts Valve Orifice ≤ 0.032″: 5 Watts Without Valve: 2 WattsDeviceNet™ Valve Orifice > 0.032″: 10 Watts Valve Orifice ≤ 0.032″: 7 Watts Without Valve: 4 Watts |

| Certifications/Approvals | ISO/IEC 17025:2005 CE: EMC, RoHs, PEDUL Listed/Recognized: Class 1, Div 2, Group A,B,C,D Class 1, Zone 2, IIC T4, Class II, Zone 22ATEX: II 3 G Ex nA IIC T4 Gc II 3 D Ex tc IIIC T 85°C Dc IECEx: KOSHA: |

| Size | Large |

| Environmental Compliance | RoHS Directive (2011/65/EU) REACH Directive EC 1907/2006 |