Features

|

Benefits

|

Applications

|

Specifications |

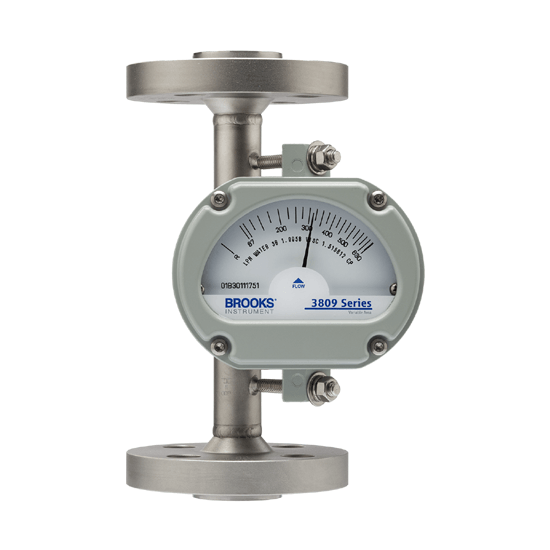

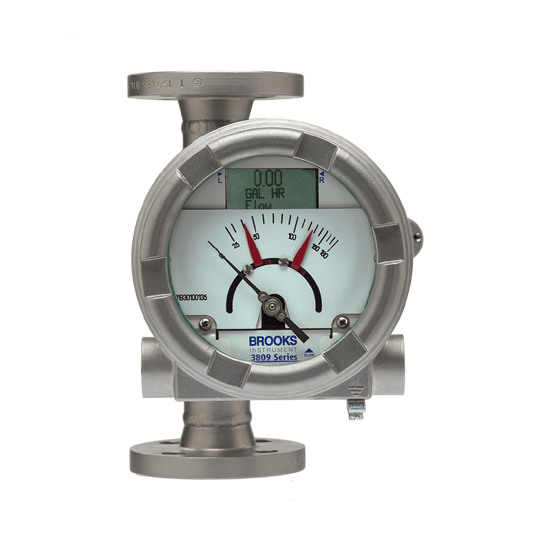

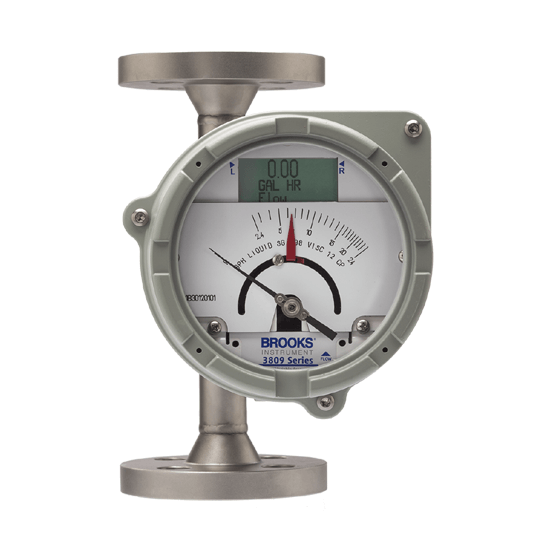

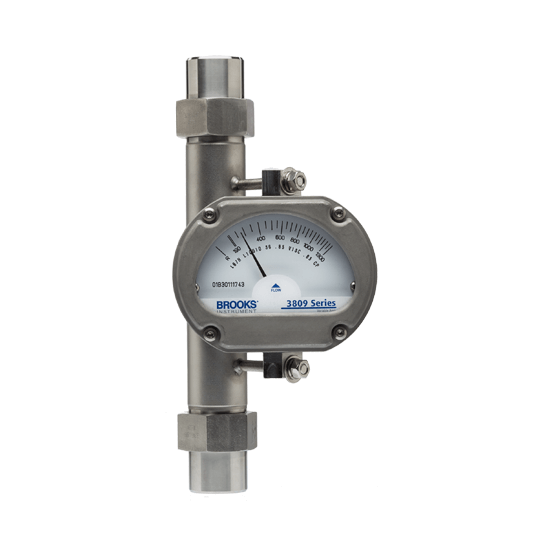

| Product Type | Metal Tube Variable Area Flow Meter Applications: Clean liquids, gases and steam |

| Differentiator | Repeatable flow measurement even at low process temperatures down to -198°C / -325°F and high process temperatures up to 420°C / 788°F

Designed for high process pressures 1379 bar(a) / 20,000 psig Customers can rely on a proven flow measurement technology that works when electrical power is not availableand at the same time communicate to controlsystems over analog- or digital interfaces Optional local operator interface with LCDscreen for easy operator control and alarm functions that meet SIL 2requirements A selection of corrosion resistant wettedmaterials and indicator housings to fit your demanding applications Product is designed to meet ASME B31.3 which isa requirement requested at the world’s major industrial facilities. Productdocumentation, material traceability and project planning perfectly blends withthe needs of Engineering Procurement Contractors (EPC) system integrators |

| Flow Range (Full Scale Capacity) | Refer to Capacity Tables in Data Sheet

Water Air |

| Pressure Drop | See Capacities & Pressure Drop Tables in Data Sheet |

| Accuracy | ±2% Full Scale / Class 2.5 VDI / VDE ±1% Full Scale / Class 1.6 VDI / VDE ±5% Full Scale / Class 4 VDI / VDE ±3% Full Scale / Class 2.5 VDI / VDE |

| Repeatability | All options except ELF: 0.25% Full Scale ELF: 1% Full Scale |

| Mechanical | |

| Metering Tube Material | 316 Stainless Steel |

| Scales | Single or Dual Detachable Aluminum Plate |

| Scale Graduations | Choice of direct reading units or percentage of maximum flow with factor tag. |

| Float Material | 316L Stainless Steel, Alloy 625, Hastelloy C-276, Titanium GR II, Monel K-500, PVDF |

| Housing | Die cast Aluminum (Alloy 380) with Epoxy Paint Coating with glass window Die cast Aluminum (Alloy 380) with Epoxy Paint Coating with shatterproof glass window Cast 316 Stainless Steel with glass window Cast 316 Stainless Steel with shatterproof glass window |

| O-Ring Materials | Flange option or Male NPT: No O-rings Female threaded options: Viton fluoroelastomer, Kalrez fluoroelastomer, PTFE Teflon |

| Connection Materials | 316L Stainless Steel, Alloy 625, Hastelloy C-276, Titanium GR II |

| Process Connections | All materials: NPT, Rc (BSP) Female All materials: 150#, 300#, 600# Flanges per ASME B16.5 All materials: DIN PN40 Flanges All materials: JIS B2220 DIN 10K, 20K Flanges |

| Optional Equipment | |

| Alarms | Inductive Switch – All Sizes |

| Transmitter | 4 – 20 mA with HART Communications |

| Diagnostics & Display | |

| Fluid Temperature Range | Refer to temperature cut-off tables by option in Data Sheet |

| Max Temperature Range | Meter

-325 to 788°F |

| Ambient Temperature Range | Refer to temperature cut-off tables by option in Data Sheet |

| PED Categories | Refer to PED Categories in Capacity Tables in Data Sheet |

| Max Pressure | Refer to Pressure/Temperature Tables in Data Sheet |

| Ratings | |

| Electrical | |

| Certifications/Approvals | International agency approvals for alarm and transmitter SIL 2 for alarm option International Calibration Certificate (ICC) Material certifications Liquid Dye Penetrant Positive Material Identification NACE MR 01-75 & MR 0103 Pressure Test certificate Oxygen Cleaning certificate Certificate of Conformance |

| Compliance | |

| Digital Communication | HART® 7 FOUNDATIONTM Fieldbus (EMERSON™ qualified for Delta V control system and AMS device manager) |

| Analog Communication | Transmitter 4-20 mA |