ADVANTAGES

|

APPLICATIONS

|

CHARACTERISTICS

|

Technical specifications |

Leak ranges

- ± 200 Pa (model 1)

- ± 2000 Pa (model 2)

- ± 20000 Pa (model 3)

Accuracy at 20 ° CModels 1 and 2

- 10% to 100% of the range: <± (1% reading + 1 digit)

- 0 to 10% of the range: <± (0.1% range + 1 digit)

Model 3 : <± (1% range + 1 digit)Resolution4 digits on screenTemperature coefficients

- Zero: automatic

- Span: <0.15% per ° C

Long-term stability (span)<± 1% per yearPRESSURE MEASUREMENTPressure ranges

- ± 99.99 mbar

- ± 200 mbar

- ± 999.9 mbar

- -1 bar at +4,000 bar

- -1 bar at +8,000 bar

- -1 bar at +9,999 bar

- -1 bar at +14.00 bar

- -1 bar at +30.00 bar

Accuracy at 20 ° C

- 10% to 100% range: <± (1% reading + 1 digit)

- 0 to 10% range: <± (0.1% range + 1 digit)

Resolution4 digits on screenTemperature coefficients

- Zero: <0.05% per ° C

- Span: <0.1% per ° C

Long-term stability (span)<± 1% per yearELECTRICAL DATASupply voltage24 Vdc ± 10% <500 mAElectric connections

- Power supply: 2 removable screw terminals

- Outputs: 20 channels with removable screw connector

- Inputs: 16 channels with removable screw connector

- RS232: 9 pin D connector

- RS485: 5 pin removable screw connector

- LAN: RJ45 connector, 10 base – T / 100 base – TX Ethernet

- USB: USB type B connector

Control inputsUp to 24 opto-isolated inputs, active by high or low. 5 Vcc at 24 Vdc with 10 kΩControl outputsUp to 32 active outputs per transistor (PNP). 12 Vdc at 45 Vdc, 120 mA (per channel)PNEUMATIC DATACompatible mediaClean and dry air or non-corrosive gases.Service pressureMaximum 10 bar, minimum 5 barPressure supplied to the regulatorMáximo 16 bar o 35 bar para la opción equipo 30 barPneumatic connections

- Air supply: 6 mm quick connector

- Power supply to the regulator and output: 8 mm quick connector

- Test / reference: 1/8 “BSPF

- Up to 5 programmable pneumatic outputs: fast connection 4 mm

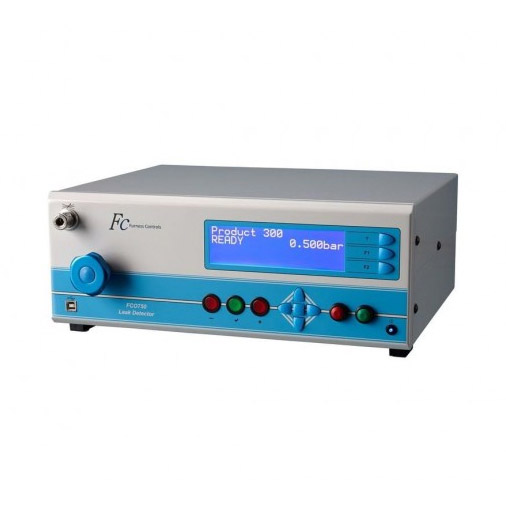

Water tightness<0.2 cc / hourBUILDINGBoxMade of steel, optionally manufactured in a 19 “3U rack.Dimensions294 mm x 232 mm x 145 mmWeight8.5 kg ± 0.5 kg

|

LEAK MEASURES

|